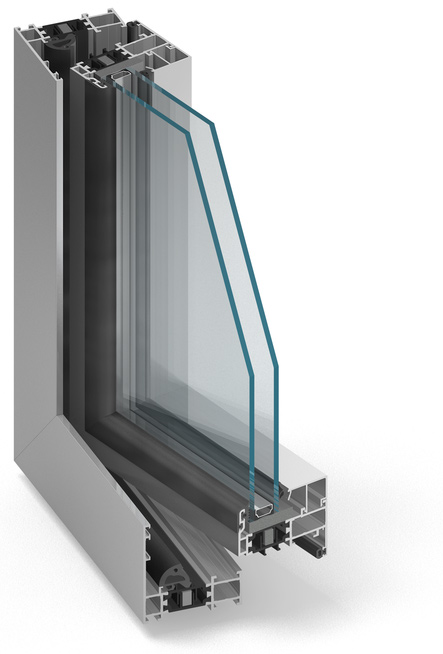

Three-chamber profiles of the system, thanks to special seals made of two-component synthetic rubber EPDM: solid and cellular ensures very good durability and thermal insulation. Rubber provides resistance to aging during long-term use.

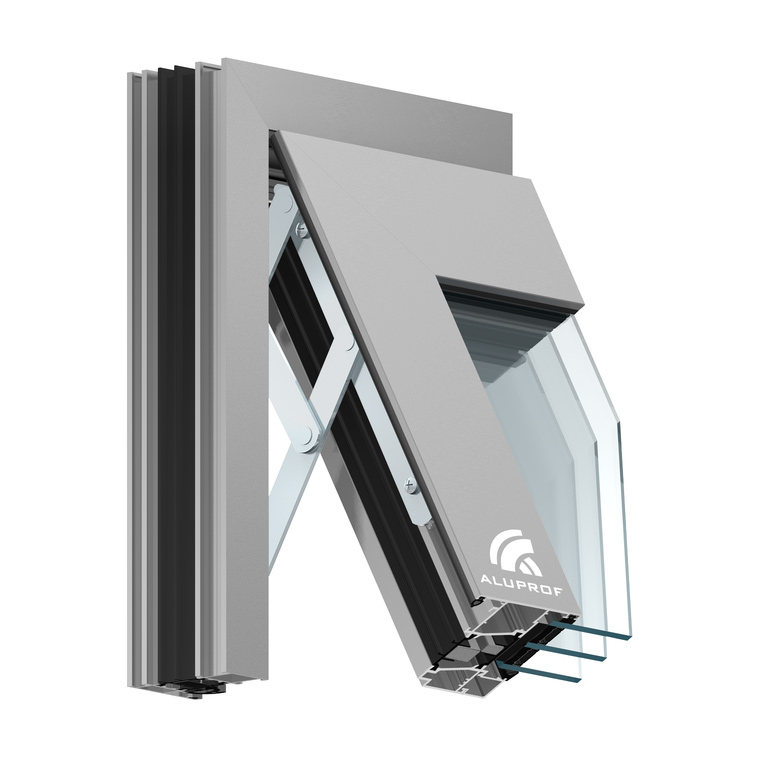

Wide colour range available in standard palette allows to fully adjust the profile’s appearance to the building’s design. Colour coatings applied by the powder painting or anodising method show incredible resistance to harmful external factors.